Ever since the Chinse invented the process of turning wood pulp into paper sheets, the world has been in love with this versatile product. But this process is both a great boon and a bane. Yes, we get everything from package labels to money to drawing sheets from it. But lakhs of trees are cut down every year to make paper, which can be used and tossed in ten minutes. The tree takes a lifetime to grow.

Are there any solutions?

We can do our best to reduce, of course. Recycling is a halfway solution since printed paper, with its dyes, glues and inks, makes dark and rough sheets when recycled. and cost more than fresh ones. There is reuse as well. We are certainly innovative with it in India. Street vendors wrap the goods in old notebook paper, homemakers line shelves with old newspapers and practically every home has an old paper stapled together as a writing pad. But these methods are not enough.

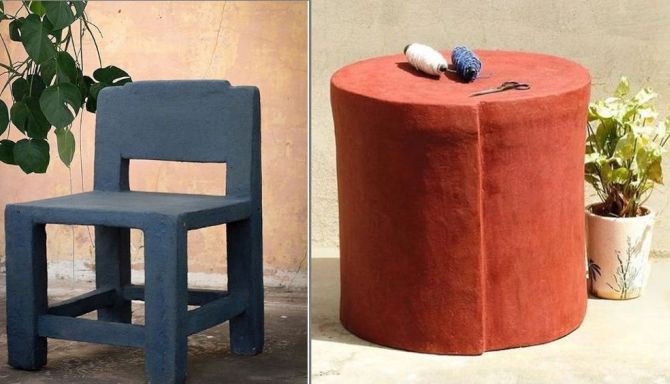

The idea of making furniture out of waste paper first came to Spriha about ten years back when she was a student at a design school. As a part of the project assigned to them, they had to either work under someone or carry out independent work.

Experimenting with Materials

Brought up in Assam, Spriha moved to Bengaluru to pursue a degree in Product Design from the Srishti Institute of Art, Design, and Technology.

After deciding to use papier mache as her material of choice for her three-month-long diploma project, a long period of experimentation followed.

“Initially, when I was making the furniture, I was using strong adhesives made with chemicals. That had a negative impact on my health. I began questioning myself about what is the point of making a product if it isn’t maker-friendly. That is when I decided to look out for natural materials that ensure the wellbeing of whoever was making the furniture,” she says.

Spriha then started experimenting with materials like corn starch, potato starch and even rice. Finally, she settled on tapioca glue but realised that it would, unfortunately, leave an odd smell. By this time, she had finished her course and decided to take a break to dabble in pottery.

What is Water Resistant Plywood?

Furniture and cabinets that are constantly exposed to water should be made with water-resistant plywood. The water-resistant quality comes from the bonding material, usually a synthetic plastic resin that renders it impermeable to water. It is favoured for areas like kitchens and bathrooms where the chances of prolonged exposure to water are high.

Plywood is commonly available as boards of 4’ x 8’ or 3’ x 7’, and as variants of these sizes. The available thickness ranges from 3 to 25 mm. Plywood boards that are pre-veneered or pre-laminated help to cut down the finishing time. However, only certain finishes of veneer or laminate are available in such pre-finished ply boards.

For a better choice of colors and finishes, pick the laminate or veneer separately and have it pasted on the ply by the carpenter.

Features and Benefits of Water Resistant Plywood

Plywood is stronger and more durable than MDF. It is used for high-end furniture and cabinetry.

As it is comprised of veneers of wood stacked on top of each other, the core, front and back faces of the board can be of different materials.

A cross-section through the board will clearly show the different layers in the section.

Phenolic resins are used as a bonding material. They give plywood its waterproof properties.

It is dimensionally stable due to the alternate layers of plies and cross-grain construction within the board.

Plywood has a high screw holding strength and grips screws easily.

It is termite and borer resistant and not susceptible to fungus or mould.

By using veneers on the surface of plywood, you can get a realistic wood finish on the furniture. It can be laminated as well.

For shutter and boxes, the cut outer edges of the plywood must be sealed with edge banding tape, membrane or wooden beading to increase its durability.

Plywood cannot be carved or moulded into different shapes like MDF, as the core is not uniform.

Plywood is more expensive than MDF but is cheaper than solid wood.

Water-resistant plywood is used in kitchens, utility areas and bathrooms